Add to Cart

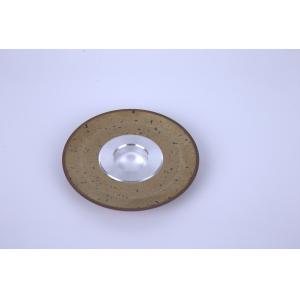

For grinding tungsten carbide tipped circular saw blades

Features:

1. Good sharpening and high efficiency

2. Durability

3. Fit to coarse and fine grinding at same time

4. Make workpiece a good flatness and roughness

| Specifications: | |||

| Common Shape | Wheel Size | Grit Size | Classic Specification |

| Face: 4A2, 12V2, 12V9 Top: 12A2, 6A9 Side: 1A1, 3A1, 14A1 |

100D 125D, 150D | Face:400#, 600# Top:325#, 400#, 120/400 Side:120#, 240#, 400#, 600# |

6A9 125D*18T*32H*5W*5X 3A1 100D*10T*32H*5W*5X 12V2 125D*13T*32H*2W*4X |

| Application | ||||

| Industry | Workpiece&Material | Machine | Bond | Working Data |

| Woodworking Industry | Tungsten Carbide Cermet |

Vollmer Biberach Beta |

Resin | |

Application

1.PCD, PCBN, Precision grinding of ceramic tools

2.Hard Alloy cermet cutting tool for efficient grinding

3. Woodworking saw blades, band saws, milling cutters, drill bits, etc.

4.Monocrystalline silicon, high precision electronic glass precision high-quality processing

About Us

Xinzheng Dia Abrasives Co., Ltd is a professional manufacturer of diamond and CBN grinding wheels with an capacity of 20,000pcs/month. Its products cover resin, vitrified, metal, electroplated and hybrid bonded diamond and CBN tools, which have been widely used in the fields of Automobiles, Bearing, Aerospace, Magnetic materials, Compressor, Ceramics, Tools, Molds and so on.

Dia Abrasives manufactures a large variety of superabrasivs products that are often used for grinding cemented carbide, ceramic, quartz, glass, ferrous metal and other tough materials. We have more than 10,000 sets of mold ensure 30,000 wheel specifications available. We develop 50 bond formulations to meet different application and customer requirements.